Here at New Motion Labs , we’ve been working non-stop to develop and promote the latest technologies in the field of mechanical engineering. We want to spark curiosity and be part of a new revolution in mobility and automation, bringing new tech that will disrupt and improve our world.

Here’s how.

The Link Drive is one of the biggest breakthroughs in mechanical power transmission since the invention of the roller chain.

The original roller chain is a type of chain drive which has been used for over a century in the transmission of mechanical power for a range of devices, from standard conveyor belts to printing presses and bicycles. Hans Renold is credited with its invention in 1880, but the roller chain’s design was actually inspired by sketches made by Leonardo Da Vinci in the 16th century. So maybe it’s time for a change?

Enter: the Link Drive

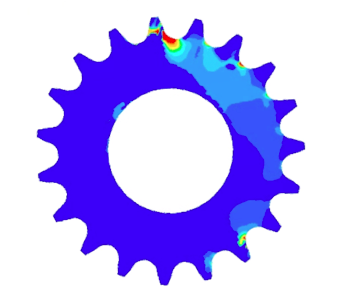

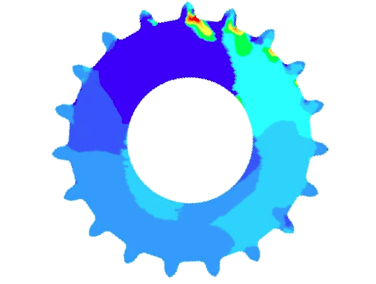

The Link Drive uses a revolutionary new method of engagement to distribute transferred power much more effectively than a traditional roller chain. The result? Step-change increases in efficiency, lifetime and miniaturisation.

The Link Drive reduces friction, noise, wear and efficiency losses, radically improving power distribution, efficiency and system lifetime, whilst requiring less maintenance than conventional technologies. Not only that, it transfers the same amount of power as a traditional roller chain despite being smaller and lighter.

The Link Drive’s lightweight design, advantages in terms of power distribution, reliability and durability make it ideally suited to use in industry, from robotics to automotive manufacture and conveying.

But, Why?

● Traditional roller chains generate high levels of friction, are noisy, susceptible to wear and generally inefficient.

● Gear drives are not only heavy and noisy, they also struggle to transfer power over large distances.

● Belt drives are prone to slippage, lose excess heat energy because they rely on friction to transmit power, and are further disadvantaged by their large size and short lifetimes.

The Link Drive solves all of these problems, addressing issues with efficiency, power, reliability and wear with its revolutionary engagement mechanism.

Industry is ready for a change. And that change is the Link Drive.